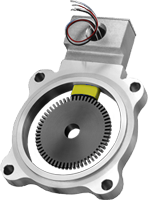

ML-TRIM (Replaced by the MLP-TRIM)

|

|

|

Digital Motion Controller in an Economical Package

OVERVIEW

The ML-TRIM is universal digital controller designed to provide closed-loop speed control to any AC/DC/Vector drive. With 0.01% set speed error, the ML-TRIM can accommodate demanding electronic gearing applications often found in web handling, and extrusion processes. The MLP-TRIM has all the capabilities of the ML-TRIM, but with an Analog Input and zero cumulative error in follower mode.

FEATURES

-

No complicated programming required; interfaces with nearly any drive

-

10 millisecond control loop for precise speed control

-

Optical isolation to protect against electrical noise

- Built-in LED display can be scaled to engineering units such as feet-per-minute

Digital Motion Controller with Built-in 1/4 to 2 HP DC Drive

OVERVIEW

The ML-DRIVE is a cost effective integrated motion controller + DC drive. The built-in SCR drive can handle up to 2 HP Permanent Magnet DC motors and has a settable current limit of 0 to 10 Amps. The digital motion controller provides closed-loop speed regulation for applications that require precision speeds and ratios. The MLP-DRIVE has all the capabilities of the original ML-DRIVE, but with an Analog Input and zero cumulative error in follower mode.

FEATURES

-

No complicated programming required

- Speed controller with built-in DC drive for up to 2 HP motors

-

10 millisecond control loop for precise speed control

-

Optical isolation to protect against electrical noise

- Built-in LED display can be scaled to engineering units such as feet-per-minute

APPLICATIONS

|

Blending: Metering pumps, screw augers, feeder conveyors can be precisely ratio controlled for perfect recipes |

Conveyors: Process conveyors or transfer conveyors can be coordinated with precision. Product spacing can be adjusted. Inverse "time-in-oven" setpoints are available. |

|

|

| Web Drives: Film, paper, fabric processing with dancer control. Use simple on-off photo eye for loop control, or use dancer pot or sonic sensor. |

Extruders: Maintain constant volumetric die flow rates. Precisely control take-away conveyors, cooling conveyors, sizing rolls and other downstream motors in extruder processes. Many more applications in blown film lines and coextrusion processes as well. |

|

|

ML-TRIM User Manual (806KB PDF)

ML-TRIM User Manual (806KB PDF) ML-TRIM Install & Start Up Guide (61KB PDF)

ML-TRIM Install & Start Up Guide (61KB PDF) ML-TRIM Fax-In Support Sheet (8KB PDF)

ML-TRIM Fax-In Support Sheet (8KB PDF)